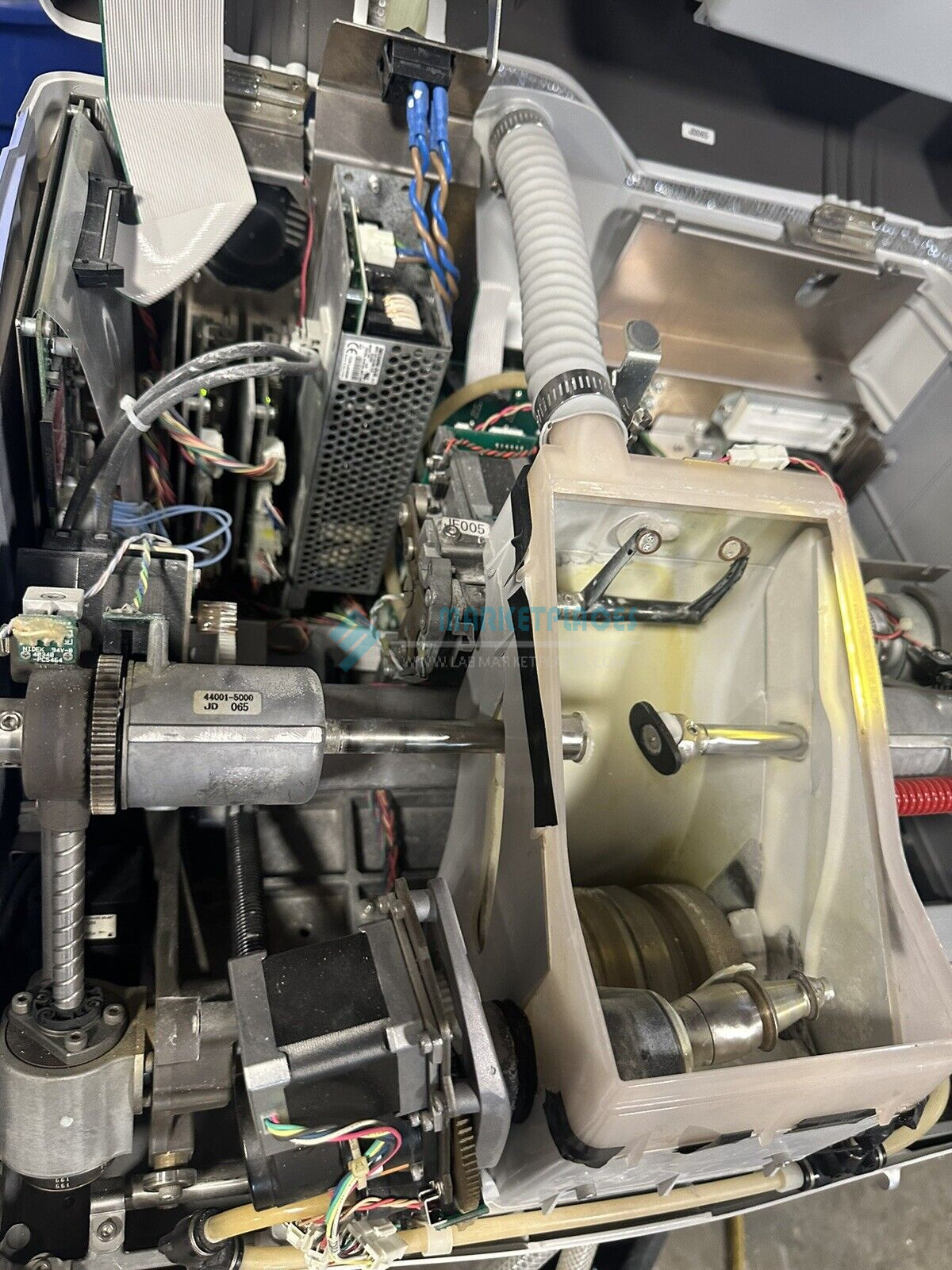

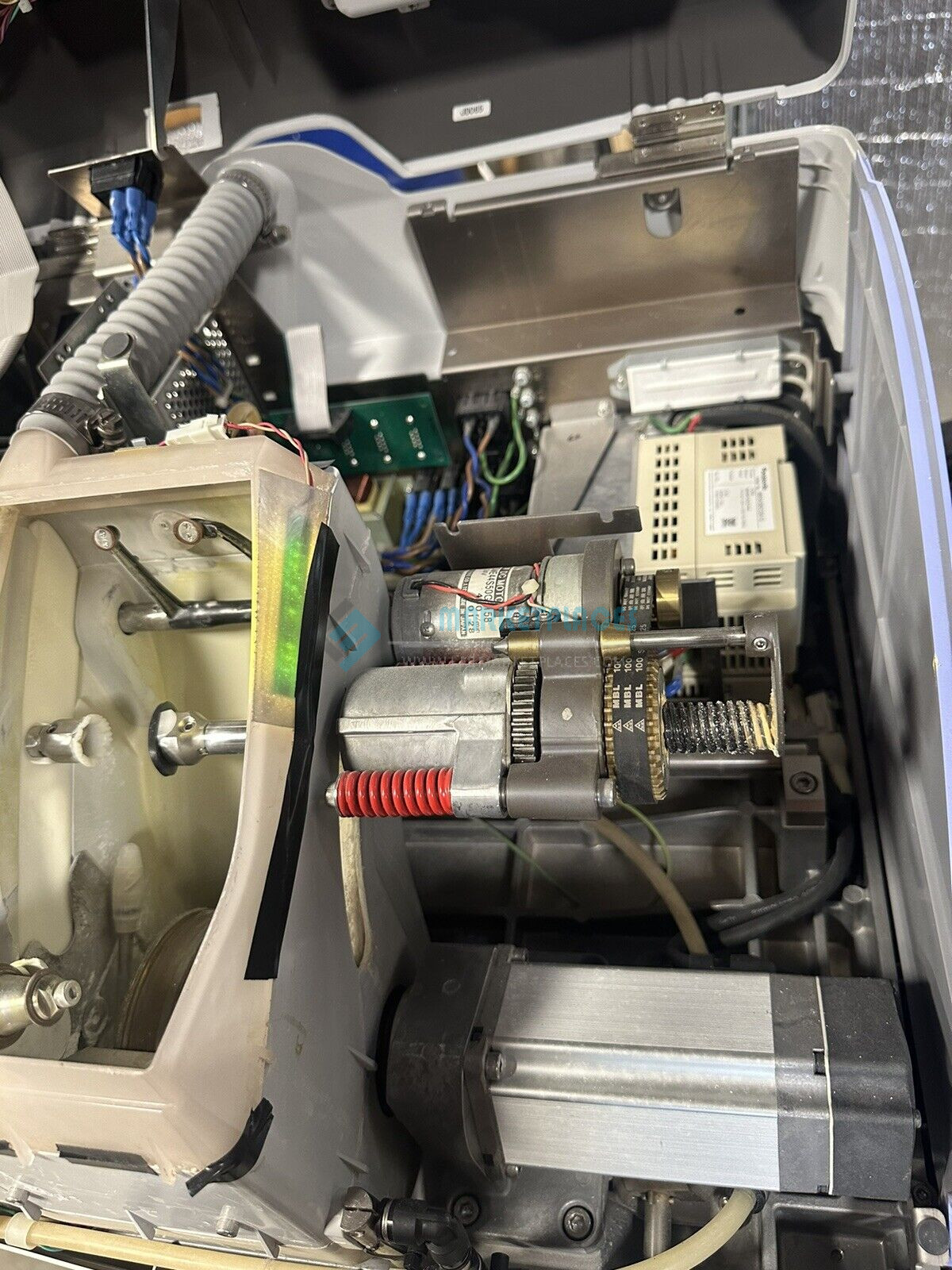

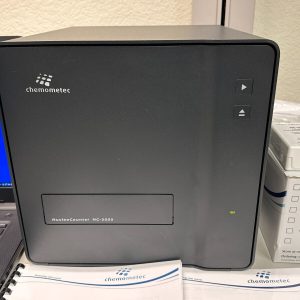

Santinelli Nidek LEX 1000 PLB 8 Patternless Edger and Lex drill

By processing the front and rear bevels separately, the Lex 1000 produces the ideal bevel profile for highly curved lenses. Even the most difficult eyeglasses can have its bevel adjusted by the Lex 1000. Around the lens’s perimeter, this unique method produces a uniform and personalized contoured bevel. The Lex 1000 consistently produces a pristine appearance with a precise fit and bevel.

Direct Drive Lens Rotation

The most cutting-edge computer-aided engineering (CAE) methods were used in the creation of the Lex 1000. With each cut, a stable cylindrical axis is guaranteed via a direct-driven gearing system. The chucking pressure is maintained steadily by an inbuilt stabilizer without damaging the lens coatings.

Grooving

A specifically made grooving wheel on the Lex 1000 produces an exceptional groove quality with “pin-point” accuracy. When positioned at the ideal angle, a smaller groove wheel diameter perfectly grooves high-base curve lenses.

Polyurethane Lens Processing

Sunglass lenses made of polyurethane can be processed using the Lex1000.

Advanced Soft Grinding Mode

The most cutting-edge technology for processing coated lenses is found in the Lex1000’s Advanced Soft Grinding Mode. To prevent axis movement, this technology keeps an eye on the grinding pressure and keeps it at the ideal level for the duration of the cycle.

“Whisper Quiet” Operation

The Lex1000’s noise level is incredibly low thanks to a cutting-edge processing management technique. Another important benefit is the noise barrier that the grinding chamber lid seal offers. All edging cycles preserve the low volume, allowing lenses to be treated with “Whisper Quiet” operation.

Features:

- For the smaller frames of today, the minimum B measurement is 15.5mm.

- The new Nano Cup/Block can process dimensions of at least 15.5 mm? B? The new pliable ring adapter allows you to treat ultra hydrophobic lenses without worrying about axis displacement.

- Integrated high curve beveling that is completely programmable and customizable

- You can set the bevel to the front, back, or any other position and ratio.

- Able to glaze up to ten or twelve base lenses

- Safety bevels, polishes, and grooves

- Removes all lens components.

- Super hydrophobic coatings can be processed in an advanced soft grinding mode without the chance of slippage.

- There are five distinct system configurations, offering the most options on the market.

- Add on Drill: The retro-fit LEX Drill allows you to update the system to rimless glazing whenever you’d like.

- Superior drilling: 3D drilling from 0 to 30 degrees makes it simple to drill even difficult holes, including countersunk, twin, rectangular, jewel, or slot holes.

- Slim design: the LEX Drill can fit into even the tiniest laboratories or workshops because it is only 14.5 cm wide.

Lex Specifications

- Grinding system: Patternless

- Tracer: Built-in

- Wheel configuration: Type PLB-G, Type PL-8, Type PLB-8, Type PLB-2R8

- Water supply system: Pump circulation or direct connection to tap water

- Power supply: AC 115 / 230 V, 50 / 60 Hz

- Power consumption: 1.5 kVA

Lex Drill

- Hole diameter: ø0.8 to 4.0 mm (0.01 increments)

- Hole depth: 6.0 mm or less

- Range of hole milling: ø32 to 75 mm from lens rotation axis

- Direction of hole milling: Automatic tilting / Manual tilting 0 to 30º

- Slotted hole width: ø0.8 to 4.0 mm (0.01 increments)

- Slotted hole depth: 6 mm or less

- Slotted hole length: 20 mm or less

- Power supply: 100 to 120 / 230 V ±10%, 50 / 60 Hz

- Power consumption: 90 VA

Standard accessories:

- Pliable cup

- Pliable cup for highbase curver

- Double-side adhesive pad

- Cup remover

- Dressing stick for roughing wheel of glass lenses

- Dressing stick for finishing wheel

- Compound kit for polishing wheel

- Pattern setting unit

- Standard frame

- Standard pattern

- L-shaped tube

- Hexagonal screwdriver(2.5 mm)

- Hexagonal wrench

- Drain hose adapter

- Power cord

- Tray

- Spare fuse

- Accessory case

Reviews

There are no reviews yet.